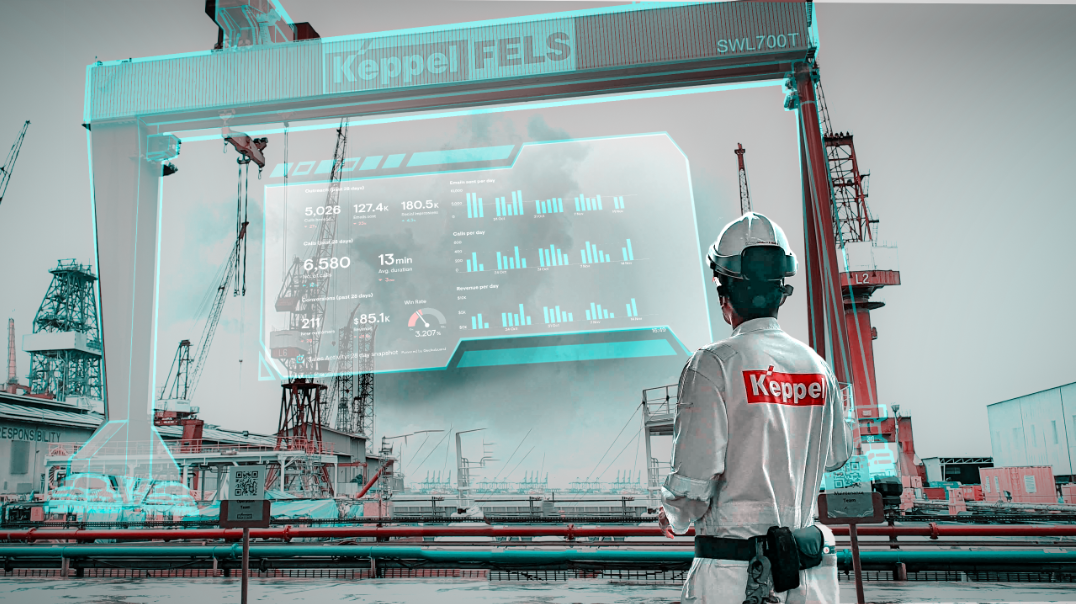

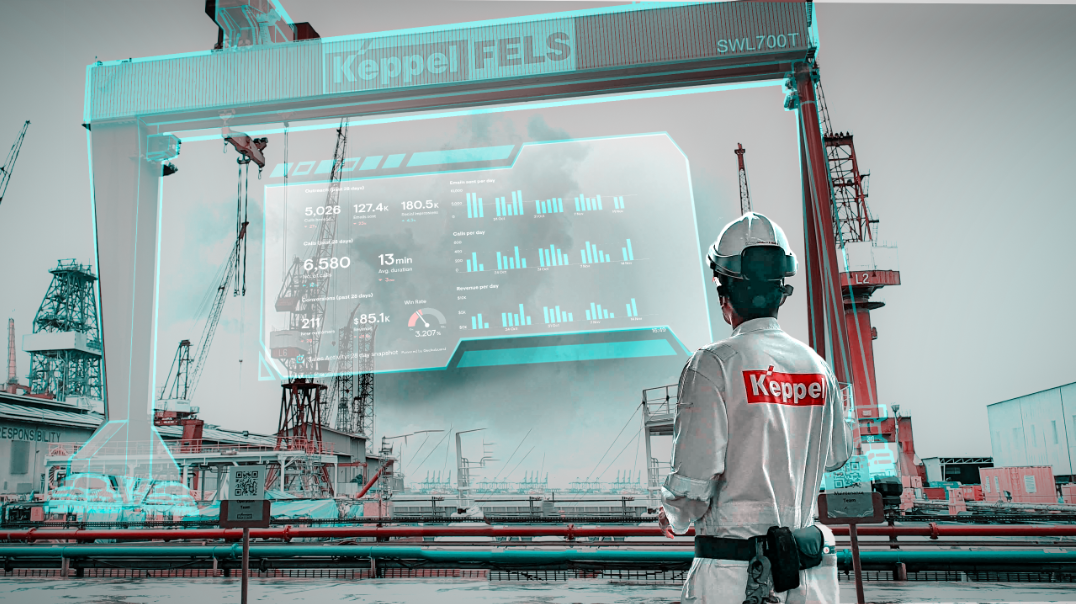

Keppel Shipyard's 5G-powered SpatialWork digital transformation enhanced efficiency, reducing on-site inspection hours by 50% and boosting field engineer productivity by 40%.

After several user research sessions, SpatialWork has been deployed at the shipyard to optimize the various phases of Keppel’s business operations. While compatible with 4G, the system performance is also enhanced with the 5G infrastructure, making it one of the first three commercial 5G projects in Singapore and the first 5G shipyard in Southeast Asia’s maritime industry.

At the Design and Construction Stage, SpatialWork allows workers such as engineers, clients, and classification societies in various regions to conduct remote virtual walkthroughs, perform pre-construction feasibility assessments simultaneously, validate correct specifications for construction, and identify potential engineering design issues as early as possible. This helps mitigate pre-construction risks. The solution is useful in facilitating collaboration across different yards and locations (i.e. Southeast Asia, North Asia, Europe, South America) where various vessel components are being constructed. SpatialWork functions commonly used at this stage are SpatialPlanner, SpatialViwer (PC and XR), SpatialAnnotation, voice call and augmented video call .

The Digital Twin solution has successfully reduced the time in tasks which require remote operational collaborations such as inspections, surveys and audits, as well as self-guided machine maintenance. It has also reduced the time needed for engineers to assess sites with safety hazards while ensuring operations efficiency. As a result, Keppel achieved 40% improvement in field engineers’ efficiency, and 50% reduction in man hours required for on-site quality inspection.